Note from the guest author Martin Kessler: After reading Cedric Delzenne’s guest post on the lessons he learnt as a first time founder, I felt inspired to write something about my own learnings. Over two years at Phonejoy had left me with plenty of hardware development and manufacturing lessons to draw from. I hope that with my post I can help other hardware-focused entrepreneurs in Hong Kong and around to learn from my experience.

Note from the guest author Martin Kessler: After reading Cedric Delzenne’s guest post on the lessons he learnt as a first time founder, I felt inspired to write something about my own learnings. Over two years at Phonejoy had left me with plenty of hardware development and manufacturing lessons to draw from. I hope that with my post I can help other hardware-focused entrepreneurs in Hong Kong and around to learn from my experience.

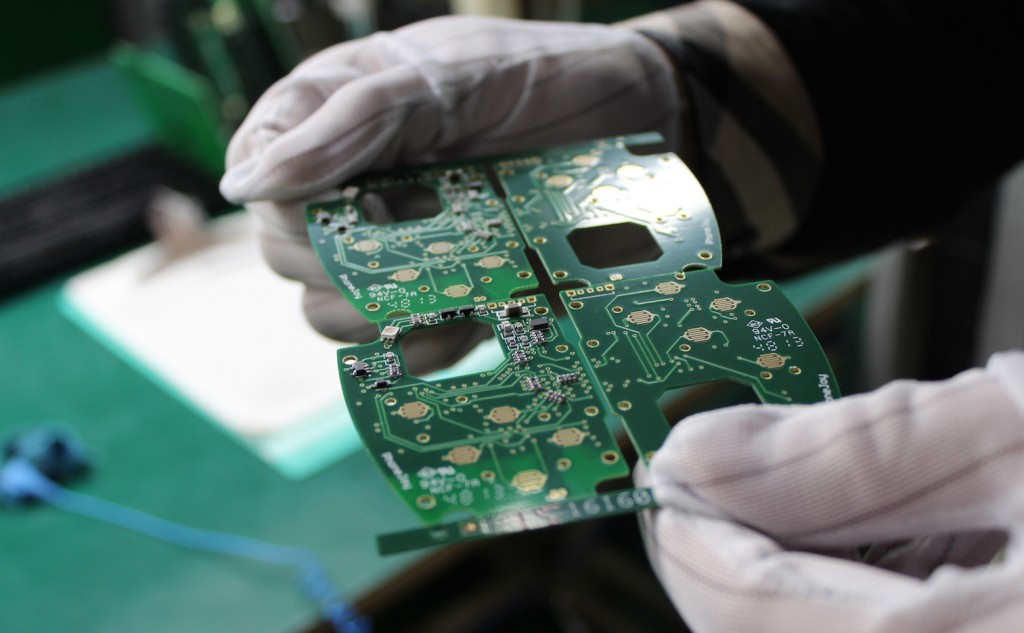

With Phonejoy, I went for the first time through the whole cycle of developing a concept, building prototypes, setting up a production line to delivering our Phonejoy game controllers to consumers. It was an agonising and long process for us that had been filled with long delays. When mentoring at the Founder Institute, an aspiring entrepreneur asked me how we were able to go on after experiencing so many setbacks. It took us a lot of persistence and looking back at our experience it could have been much much easier.

1. It Takes Planning & Expertise

Hardware is hard, and slow, and complicated. It requires lining up lots of moving pieces, and unlike with software it cannot be all done by two guys with MacBooks. Ironically this is almost how we first started Phonejoy. Our founder team, at first did not expect all the challenges a hardware startup faces.

In fact, in the beginning we just started building. We hired contractors where we could not excel with our own skillset. Along the way we learnt most of the development and manufacturing processes. It is needless to say that this procedure created a number of schedule and cost issues for us.

2. Beware of Complexity Cost

Features, even at this early stage, will come to haunt you later if you cannot command top dollars when you sell them. Margins (or the lack of) are business killers. It’s never too early to think about your costs. Every penny counts. Typical consumer products see a 3-4x increase to their shelf cost.

If your Bluetooth module costs you US$1 more than you had anticipated, then your retail price will rise another US$3 – US$4. In the price sensitive consumer market your cost can turn out to be deadly trap. Likewise every screw you add, may only add a penny to your bill of material, but they will also prolong your product assembly by a few more seconds. With labor costs in China rising nearly 20 percent every year, every second starts to matter more than ever.

Generally speaking, you also want to make sure that you use off-the-shelf components. Any component you can get from major online suppliers such as Mouser, Digikey, Sparkfun and even Taobao are often available en masse and come with short lead times. You want to avoid components that are made-to-order. Otherwise you will likely build up a large inventory for component lead times longer than 60 days.

3. You Are Not Apple!

Apple products come with an amazing industrial design that leaves many to awe. Now, you might want to aspire to that same level. However, take note, if Apple wants to CNC mill a million MacBooks every year they can do it. They just need to buy 10,000 CNC machines. But you and your contract manufacturer will likely not be able to do so.

Early on we had designed our product to rely on manufacturing processes such as laser cutting millimeter thin stainless steel plates with ultra low tolerances. When we received quotes at prices of about $1 a piece, we flat-out rethought the design to allow for the old but proven technique of metal stamping.

Likewise, those fancy packagings by Apple that are often made out of polycarbonate and ABS/PC mix molded material; or those four color, double-walled, matte boxes with high-density foam inlays? Forget about them, it’s not unusual for these to cost you more than $5-10 per unit. Recycled cardboard is your friend instead.

A thick carton box enables you to ship product straight to your customers’ door step without having to repack it in an outer shipping carton. Cost? No more than $0.50 most of the time.

4. Watch Your Cashflow & Planning

Prototypes can get expensive and so are the engineers who build them. Later your tooling, inventory buildup and marketing dollar will cost you even more so dearly. Hardware is a cashflow business through and through. You need to have a solid funding strategy if you want to succeed. We did not understand all processes and development costs involved and thus miscalculated our schedule. Upon which we had to raise further funding earlier than anticipated.

Fortunately, we managed to recover from this, but you may not be so lucky. Once your product is shipping, and for the entire life of your hardware startup, you will deeply care about the float between paying your suppliers and getting paid by your customers. If your manufacturer can provide you with 60 or even 90 days of credit and you are able to receive payment in less time you are in good shape. Otherwise this will get expensive to fund.

Banks will often only loan you cents on the dollar against existing assets. Equity often requires you to give away large chunks of your company just to fund customer demand. So do not run out of cash too early, because I can tell you from my own experience that this will be an expensive problem to fix.

5. Scale Demand First Before You Scale Your Sales Channels

Speaking of cashflow. Avoid paying too much attention to big box retailers such as Walmart, BestBuy and Target. They take higher margins, come with difficult requirements, and often unfavourable NET60 payment terms. Moreover, your product will get lost on the retailer’s shelves without an expensive display.

Unfortunately, as a hardware startup you often do not have enough leverage to negotiate with them. Direct sales and niche retailers will yield you better profit margins, payment terms and control over how your product is sold. You will need to create demand before you can afford expanding your distribution channels to bigger guys.

6. Get Experts & Manufacturers Early On Board

“If you were to ask Apple or Dell what the biggest problem they face with new products is, I guarantee you it won’t be manufacturing. Manufacturing won’t even make the top 5. But if you were to ask startups the same question, it almost always is . Think about why that is. They hire people that have done it before . It’s worth every penny.” – Ben Einstein, MD of Boston based hardware accelerator Bolt.

In the beginning we hesitated to involve manufacturers and consultants with our product too early on. Now, you might think that third parties will start stealing your idea. Yet, Chinese OEMs have rarely the time to copy your unproven concept. Instead, manage to convince them of the feasibility of your product. A manufacturer who loves your product will assist you with valuable domain knowledge on designing it for manufacturability (DFM).

Problems that may arise in later assembly can also be mitigated early on in the product’s DFM stage. Protecting your intellectual property remains important of course. Patents can help, but it takes you nearly two years until you get your patent granted in China. A patent that is just pending offers few legal remedies.

A better way to protect yourself from copycats, is to design a product that makes use of mechanics, electronics, software and has a community/brand component to it. Accept the fact that you will get copied eventually. But, if your product is more than just a iPhone case, then chances are stacked in your favour.

7.Select Your Manufacturing Partners Wisely

I often get asked about how you best find your suppliers. I have had suppliers introduced to us through my trusted network, trade shows, partners like Apple, as well as the infamous Alibaba. Alibaba works but I wouldn’t recommend it for locating your final assembly factory. In my experience, the quality on Alibaba ranges from mediocre to flat-out bad. Often mediocre can be good enough for you. But you do not want mediocre for the final assembly of your product. In fact, you may have guessed it already, the best suppliers I have had found through my own network.

Before you even start to ask for quotes, you need to visit your 3-5 most favourable candidates. This will give you a better understanding about their company and practices. At the same time a personal visit, will also demonstrate to the manufacturer that you are serious about doing business with them. As a matter of fact, you almost want to pitch them like an investor so that they can get excited about the prospect of working together with you.

A site visit often reveals whether they have the capabilities that matches your forecasted volume. Above all a personal visit also allows you to establish whether they are serious about you and excited about your product. If you cannot get to meet the factory’s boss they might be too large for you. Early on the likelihood that things go wrong and your engineer(s) will want to sleep at the factory is quite high. If you do not have access to the OEM’s “laoban” it will prove difficult to move forward at a timely pace.

From there on prepare a good request for quote (RFQ) package so that the OEM is able to understand your product well enough. You will want them to quote for the cost of goods sold (COGS) and schedule. Use a fill-in-the-blank approach for your bill of material, labor costs, margins, fixed costs (tooling and non-recurring engineering) and schedule. This approach will afford you greater transparency to compare the manufacturers objectively. Aside of that you may want to ask to be introduced to their customers so that you can get more feedback on how they work.

8. Not Crowdfunding Is A Mistake

If you have developed a consumer product, then crowdfunding is your place. Kickstarter had allowed us to launch Phonejoy without having a finished product. In fact, with crowdfunding you are able to accomplish multiple goals at once:

- test market-interest

- collect pre-orders (or interest free cash, remember cashflow)

- getting attention of individuals or firms interested in investing in your product or startup

- generate publicity

- bring in your customer feedback early on

By making use of crowdfunding you deleverage risk on many fronts. Not going the crowdfunding route today anymore, would be a fatal mistake.

9. Plan Your Crowdfunding Campaign Well

With that said, crowdfunding can be a double edged sword. Only launch your campaign once you have your manufacturer on board and a firm understanding of the schedule. Bootstrapped as we were, we crowdfunded too early with a prototype that was not half as good as our finished product. As we crowdfunded too early our schedule was also much harder to predict. This lead us to an unfavourable long delay of over 9 months.

Be careful about crowdfunding stretch goals and backer feedback that affect your hardware development. Your supporters will often have lots of ideas of how your product could become better. We were careful enough not too allow for any modifications to our core product. But, we listened to our supporters to add extra accessories to our product which they could get at a surcharge. The added capabilities through the accessories were seen as necessary by a large amount of our backers. But they also came with extra tooling cost and development time that had to be taken care of.

10. Too Many Stock Keeping Units (SKUs) = Inventory Buildup

As hardware is cash sensitive, you will want to keep your stock as low as possible and your manufacturing lead times as short as you can. Unless ordered by a wholesale customer, avoid color and bundle combinations with different accessories. These various combinations will need to be prepacked at the assembly side, because repacking at the warehouse will end up being too expensive. You want to steer clear of having too many warehouses with a various amount of SKUs. It will become an unnecessary drain on your resources. Trust me.

Key Takeaways:

- Have basic understanding about how products move through manufacturing and distribution

- Keep it simple stupid (avoid complex processes & components, multiple SKUs)

- Find good partners and experts early on

- Always keep an eye on your cashflow. Find ways to stretch it.

- Plan and time your crowdfunding campaign well.

I hope I have not discouraged you from your own hardware adventures. Instead, I wish that my lessons drawn from our first hardware venture will shorten your own learning curve. I guess, that if after reading this blog post you start shunning feature creep like the plague, then I have probably accomplished that.

Martin Kessler is a mentor at the Founder Institute in Hong Kong. He is the Founder and former CEO of Phonejoy, a gaming hardware startup. Besides product marketing, Martin inhibits a passion for growth hacking strategies and online marketing.

In his spare time, Martin blogs about his experiences on kessler.hk. Say hello to him at martin(at)kessler(dot)hk.

Martin Kessler on Startbase.HK: Martin Kessler

Phonejoy on Startbase.HK: Phonejoy